HDPE Film

Description:

Films made of HDPE are noted for their characteristic rustle and milky colouring and

they are odourless.

By adding colour concentrates a lot of colour variants can be achieved and by means

of additives films with the desired properties can be produced. Unlike LDPE films, their

structure is duller, their strength is higher, they are hazier, and they are not shrinkable.

The thermal endurance of HDPE films is from −50 °C up to +110 °C. Under everyday

conditions of use HDPE films are resistant to most chemical substances, they do not

cause corrosion of the products packed in them, and they can be welded.

They have minimum permeability of water vapours and smells, and they transmit oxygen,

fats, and aromatic substances in a very limited amount. Generally, HDPE films are more

chemically resistant, which is given by their structure.

In the natural variant, HDPE films are suitable for direct contact with foodstuffs, the colour

variants only if the pigment content is within the concentration defined by the producer.

HDPE films are environmentally unobjectionable and recyclable, and they can be disposed

of in landfill or by combustion in which no substances harmful to the environment are released.

Main Fetures:

► Hot melt, torchable, easy to construction

► 7-30 microns thickness

► Environmental friendly, no residue

► Perforated performance, make the surface more flat

► More economical

Application:

It is used as the surface material for SBS bitumen waterproof membranes and

APP bitumen waterproof membranes.

Torchable construction, easy melt when use, no residue after melt.

Parameter:

| NO. |

Item |

Unit |

Factory parameter |

Detection method |

| 1 |

Appearance |

/ |

|

Q/TPXP1-2015 |

| 2 |

Thickness |

mm |

0.008-0.015 |

GB/T 6672-2001 |

| 3 |

Width |

mm |

1060-1070 |

GB/T 6673-2001 |

| 4 |

Max.Fd |

N/50mm |

15 |

GB/T 328.9-2007 |

| 5 |

Elongation at break |

% |

200 |

GB/T 328.9-2007 |

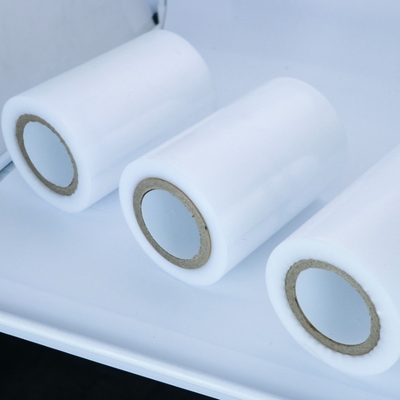

Product Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!