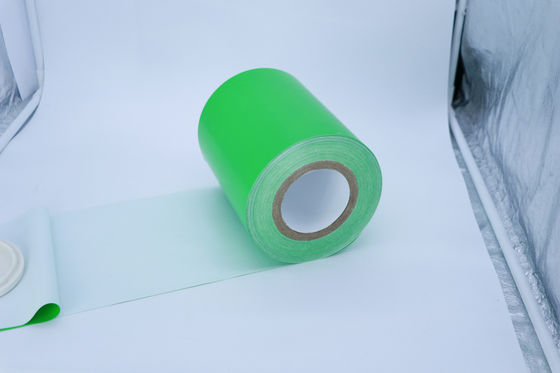

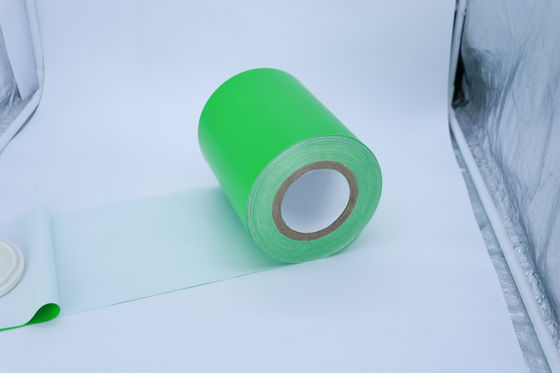

High Strength Weather Resistance Anti Corrosion Film

Description:

It is a laminated film, composite of HDPE cross laminated film and weather resistance

fluorine film.

The cross laminated film make sure the high strength, high enlongation, tear resistance,

puncture resistance.

The fluorine film is weather resistance, UV resistance, can be explosive for more than

25 years

Combine the advatages of cross laminated film and fluorine film, make it an ideal material

for weather resistance.

Application:

It is specially designed for waterproofing and tapes industry, which shall substitute

conventional exposed waterproofing material including the film for waterproofing

membranes and tapes. It also has cost effectiveness, and lasts over 25 years of

weather resistance.

Advantages:

► Excellent properties of anti-aging

► UV resistance

► Weather resistance

► Chemical corrosion resistance

► Resistance to high temperature,heat,humidity and extreme cold

► Reflectivity of over 85%

► High strength, tear resistance

Parameter:

| Detection Item |

Detection Method |

Detection Value |

Remark |

| Thickness |

UF509 |

GB/T6672-2001 |

0.128mm |

/ |

| Width |

GB/T6673-2001 |

/ |

According to customer needs |

| Max force |

UF509 |

GB/T 328.9-2007 |

MD:324N |

Rectangular spline, spline width 25mm, stretching rate: 100mm / min, fixture gauge distance: 100mm |

| TD:348N |

| Elongation at Break |

UF509 |

|

MD:406% |

|

| TD:260% |

| Tensile Strength |

UF509 |

GB/T 529-2008 |

MD:47N |

Stretching speed:250mm/min |

| TD:43N |

| Surface Tension |

GB/T14216 |

≧42dyn/cm |

Dyne Pen Test |

| Dimensional change rate |

UF509 |

GB/T 35467-2017 |

MD:0.96% |

90℃&24h |

| TD:0.77% |

| Water vapor transmission rate |

GB/T 21529 |

≦70 g/m2.24h (20um) |

38℃+100%RH |

| Electrolytic sensor method |

| Flammability grade |

UL94 |

VTM-0 |

White weathering film |

| Aging test |

PCT96 |

/ |

Yellowing index △b≤2.0, |

Temperature 121 ℃, humidity 100%, air pressure 2atm, time 48h |

| |

UV300KWh |

IEC61215 |

|

The temperature of the sample is 60 ± 5 ℃, and the total exposure is 120KWh • m2, of which UVB accounts for 3% -10%. |

| |

DH2000h |

IEC61215 |

|

Temperature 85 ℃, humidity 85% R.H., 2000h |

| |

TC400 |

IEC61215 |

|

Temperature -40 ℃ ~ 85 ℃, 6h / cycle, 400cycle |

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer.

Q2: Do you provide samples ? is it free or extra ?

A2: Yes, we could offer A4 sample for free charge but if you need in roll,

we can offer 100-200m/roll for free, but shipping cost need you to paid.

Q3: How long is your delivery time?

A3: Depends on your quantity. Generally it is 15-20 days for 20GP container.

Q4: What's your payment?

A4: By L/C, by T/T (30% deposit before production, 70% balance before loading).

Q5: What's the usage of this film?

A5: It is widely use for waterproofing membranes, self-adhesive tapes.

Q6: What's the thickness you can do?

A6: We can do as thin as 80 microns, but usually is 80-265 microns.

Q7: What's your production capacity?

A7: 500 tons per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!