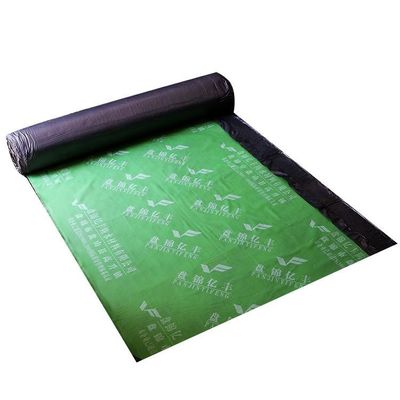

Asphalt Waterproof Membranes Application High Strength Film

Description:

|

It is a 100 micron cross laminated polyethylene film, conferring dimensional stability, puncture resistance, breaking strength and temperature resistance.

Our proprietary manufacturing process is composed of 3 steps: Original HDPE Film Blowing, Spiral Cutting, and Cross Lamination. We’ve refined this multi-step process by use imported film blowing machine can laminated machine to ensure the highest quality film for our customers.

|

Parameter:

| NO. |

Item |

Performance |

| |

|

SDM-30 |

SDM-60 |

| 1 |

Tensile Property |

Tensile Strength/Mpa ≥ |

30 |

60 |

| |

|

MaxF/(N/50mm) ≥ |

200 |

300 |

| |

|

Elongation as MaxF/% ≥ |

250 |

| |

|

Elongation at break/% ≥ |

250 |

| 2 |

Sample number of no broken tested by free-falling dart method ≥ |

8 |

| 3 |

Tear Strength(Nail Shank)/N ≥ |

60 |

| 4 |

Angle Tear Strength/N ≥ |

25 |

| 5 |

Thermal Stability |

120 ℃,10min, No bulb, No deformation |

| 6 |

Cryogenic Flexibility ℃ |

-35℃,

No fissure, No delamination

|

| 7 |

Thermal Ageing |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

80 |

| |

|

Elongation at MaxF/% ≥ |

250 |

| |

|

Elongation at break/% ≥ |

250 |

| 8 |

Artificial Weathering |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

70 |

| |

|

Elongation at MaxF/% ≥ |

200 |

| |

|

Elongation at break/% ≥ |

200 |

Note: If you have special requirements, we can customized as your standard.

Application:

► Surface/base material for CONSTRUCTION WATERPROOFING

► Material film for PERFORMANCE PACKAGING

► Carrier Material for PRINT MEDIA

► Custom Lamination

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer.

Q2: Do you provide samples ? is it free or extra ?

A2: Yes, we could offer A4 sample for free charge but if you need in roll,

we can offer 100-200m/roll for free, but shipping cost need you to paid.

Q3: How long is your delivery time?

A3: Depends on your quantity. Generally it is 15-20 days for 20GP container.

Q4: What's your payment?

A4: By L/C, by T/T (30% deposit before production, 70% balance before loading).

Q5: What's the usage of this film?

A5: It is special for the surface material when you producing SBS or APP bitumen

waterproofing membranes.

Q6: What's the thickness you can do?

A6: We can do as thin as 7 microns, but usually do 10 microns.

Q7: What's your production capacity?

A7: We have total 10 sets of machines, the production is about 1000 tons per month.

Factory Previews:

1. Taicang Production Plant:

2. Chenzhou Production Plant:

Imported film blowing machine(From Germany):

Imported laminated machine(From Italy):

QC Department:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!