High Strength Film For Waterproof Membranes

Description:

|

Our proprietary manufacturing process is composed of 3 steps: Original HDPE Film Blowing, Spiral Cutting, and Cross Lamination. We’ve refined this multi-step process by use imported film blowing machine can laminated machine to ensure the highest quality film for our customers.

Cross laminated film is puncture and weather resistant, has thermal dimensional stability and cold temperature resistance. Our cross-laminated process provides unbeaten mechanical performance and properties.

|

Parameter:

| NO. |

Item |

Performance |

| |

|

SDM-30 |

SDM-60 |

| 1 |

Tensile Property |

Tensile Strength/Mpa ≥ |

30 |

50 |

| |

|

MaxF/(N/50mm) ≥ |

200 |

300 |

| |

|

Elongation as MaxF/% ≥ |

200 |

| |

|

Elongation at break/% ≥ |

250 |

| 2 |

Sample number of no broken tested by free-falling dart method ≥ |

8 |

| 3 |

Tear Strength(Nail Shank)/N ≥ |

60 |

| 4 |

Angle Tear Strength/N ≥ |

25 |

| 5 |

Thermal Stability |

120 ℃,10min, No bulb, No deformation |

| 6 |

Cryogenic Flexibility ℃ |

-35℃,

No fissure, No delamination

|

| 7 |

Thermal Ageing |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

80 |

| |

|

Elongation at MaxF/% ≥ |

200 |

| |

|

Elongation at break/% ≥ |

200 |

| 8 |

Artificial Weathering |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

70 |

| |

|

Elongation at MaxF/% ≥ |

180 |

| |

|

Elongation at break/% ≥ |

180 |

Note: If you have special requirements, we can customized as your standard.

Advantages:

|

CROSS LAMINATED

Cross laminates two oriented polyethylene films with orientations crossed at about 90 degrees creating a tough, tear-resistant film.

|

ULTRAVIOLET RESISTANCE

UV stable grades are available for demanding outdoor exposure applications. |

TEAR RESISTANCE

Cross laminated film’s unique cross lamination process produces film that resists tearing. |

CHEMICAL RESISTANCE

Cross laminated film retains its toughness when exposed to many common chemicals. |

PUNCTURE RESISTANCE

Cross laminated resists failures from blunt objects. |

WEATHER RESISTANCE

Strong weather changes will not harm or destroy film. |

TEAR PROPAGATION RESISTANCE

Most films fail easily from a nick or hole. Our cross laminated film technology prevents further failure from minor nicks and holes. |

TEMPERATURE RESISTANCE

Cross laminated film’s unique physical properties are not significantly affected by changes in temperature. |

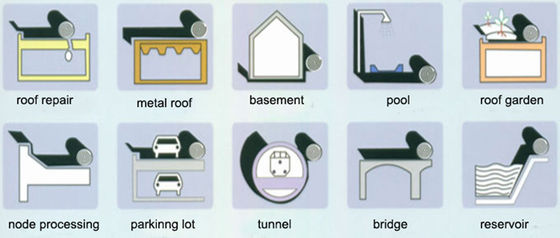

Application:

► Surface/base material for CONSTRUCTION WATERPROOFING

► Material film for PERFORMANCE PACKAGING

► Carrier Material for PRINT MEDIA

► Custom Lamination

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer.

Q2: Do you provide samples ? is it free or extra ?

A2: Yes, we could offer A4 sample for free charge but if you need in roll,

we can offer 100-200m/roll for free, but shipping cost need you to paid.

Q3: How long is your delivery time?

A3: Depends on your quantity. Generally it is 15-20 days for 20GP container.

Q4: What's your payment?

A4: By L/C, by T/T (30% deposit before production, 70% balance before loading).

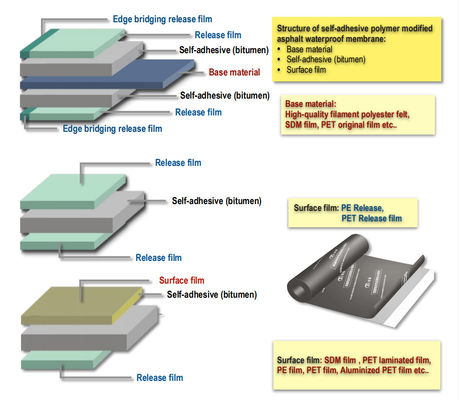

Q5: What's the usage of this film?

A5: It is special for the surface material when you producing SBS or APP bitumen

waterproofing membranes.

Q6: What's the thickness you can do?

A6: We can do as thin as 7 microns, but usually do 10 microns.

Q7: What's your production capacity?

A7: We have total 10 sets of machines, the production is about 1000 tons per month.

Why Upass:

| Upass, founded in 2008, now as a governing unit of China Building Waterproof Association, a vice chairman unit of Professional Committee of China Modified Plastic Association, an enterprise with Triple A credibility in China Plastic Association, not only assists the development of the relevant industries, but also upholds the conception of sustainable development by successive technological innovation. Upass so far has acquired over 100 of intellectual property rights. |

1. Taicang Production Plant:

2. Chenzhou Production Plant:

Imported film blowing machine(From Germany):

Imported laminated machine(From Italy):

QC Department:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!