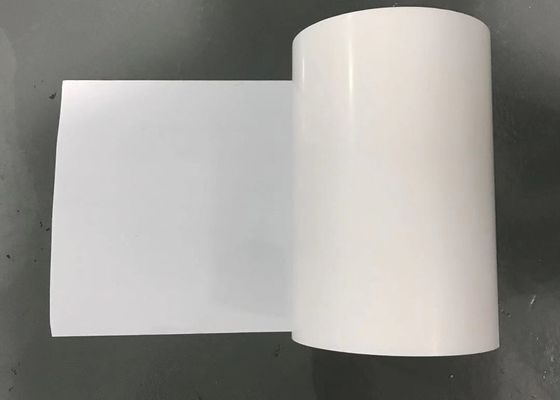

Tag Application Laminated Packaging Film

Description:

It is high-strength multi-layer composite film,It is made of HDPE as the base material,

adding plasticizer, plasticizer, stabilizer, antioxidant, UV absorber, toughener and other

additives through multi-layer co-extrusion blow molding into embryos, and then by multiple

pull Stretching, then rotary cutting into a film substrate with a horizontal and vertical

distribution of 45 °, and finally through cross-compositing. Due to its cross-stacking

structure is different from ordinary single-layer or multi-layer film, it has the thermal

stability, dimensional stability, two-way tear resistance, two-way uniform tension and high

elongation which are not available in traditional films.

Phameter:

| NO. |

Item |

Performance |

| |

|

SDM-30 |

SDM-60 |

| 1 |

Tensile Property |

Tensile Strength/Mpa ≥ |

30 |

50 |

| |

|

MaxF/(N/50mm) ≥ |

200 |

300 |

| |

|

Elongation as MaxF/% ≥ |

200 |

| |

|

Elongation at break/% ≥ |

250 |

| 2 |

Sample number of no broken tested by free-falling dart method ≥ |

8 |

| 3 |

Tear Strength(Nail Shank)/N ≥ |

60 |

| 4 |

Angle Tear Strength/N ≥ |

25 |

| 5 |

Thermal Stability |

120 ℃,10min, No bulb, No deformation |

| 6 |

Cryogenic Flexibility ℃ |

-35℃,

No fissure, No delamination

|

| 7 |

Thermal Ageing |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

80 |

| |

|

Elongation at MaxF/% ≥ |

200 |

| |

|

Elongation at break/% ≥ |

200 |

| 8 |

Artificial Weathering |

Appearance |

No bulb, No deformation |

| |

|

Subsequent MaxF/% ≥ |

70 |

| |

|

Elongation at MaxF/% ≥ |

180 |

| |

|

Elongation at break/% ≥ |

180

|

Production Process:

OUR THREE STEP PROCESS FOR MANUFACTURING HIGH STRENGTH, DURABILITY,

AND QUALITY CROSS LAMINATED FILM.

Step 1: FILM BLOWING

|

Step 2: Spiral Cutting

|

Advantages:

► Excellent dimensional stability. It can fix its own size without deformation.

► Two-way tear resistance. The vertical and horizontal mesh structure effectively solves

the phenomenon of easy wrinkling and drumming after construction

► Performance against UV radiation. The use of outdoor high temperature conditions is

guaranteed.

► High strength and high elongation performance. Excellent resistance to high and low

temperature.

► Unique puncture resistance, self-healing and continuous tear resistance and excellent

nail water tightness.

Application:

|

Widely used in anti-child tear packaging (MediCRREO); explosive packaging; chemical packaging; Blister Guard packaging; export merchandise packaging bags; building waterproof materials, postal tag, car airbag label, aviation tag Bulletproof clothing, etc.

|

About Upass:

| Upass, founded in 2008, is headquartered in New Materials Industrial Park, Qingpu District, Shanghai, and has two production bases in Taicang, Jiangsu and Chenzhou, Hunan. Now as a governing unit of China Building Waterproof Association, a vice chairman unit of Professional Committee of China Modified Plastic Association, an enterprise with Triple A credibility in China Plastic Association, not only assists the development of the relevant industries, but also upholds the conception of sustainable development by successive technological innovation. Upass so far has acquired over 100 of intellectual property rights. |

| UPASS will spare no effort in strengthening and improving the production, sales networks, service system to return the trust and support of customers, and look forward to working with you in a win-win future. |

Company History:

Main Fields:

As a new material field, functional films are also one of the top ten key fields of Made in China 2025,

and the awareness in the market is increasing. Nowadays, functional films are not only used in the

construction field, special packaging, tape, label, automobile, electronics and other industries,

but also in the fields of film filtration, air permeable film, graphene heating film, insulation film,

Anti-UV film, biodegradable materials etc..

UPASS, as a leading domestic deep cultivator of polymer functional films, has also entered a stage

of rapid development. We believe that UPASS will enter more application fields of polymer films in

near future.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!