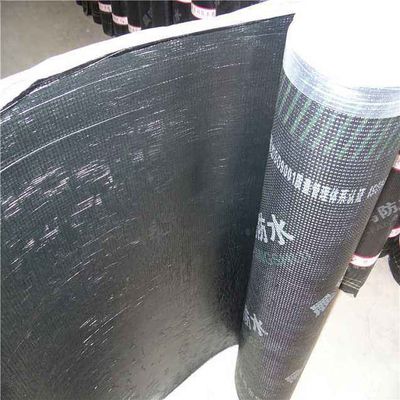

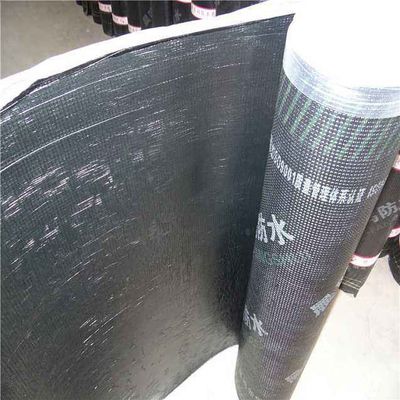

SBS/APP Waterproof Application HDPE Perforated Film

Description:

|

Perforated film also called thermofusible film, burn-off film, torchable polyethylene foil,

thermofusible HMHDPE film and torch-able film.

It is 3-layers blowing film, which made of High Density Polyethylene (HDPE).

It is special design as surface material for SBS Bitumen Waterproofing Membranes and

APP Bitumen Waterproofing Membranes, it will be melt when torch construction.

|

|

Films made of HDPE are noted for their characteristic rustle and milky colouring and

they are odourless.

By adding colour concentrates a lot of colour variants can be achieved and by means

of additives films with the desired properties can be produced. Unlike LDPE films, their

structure is duller, their strength is higher, they are hazier, and they are not shrinkable.

The thermal endurance of HDPE films is from −50 °C up to +110 °C. Under everyday

conditions of use HDPE films are resistant to most chemical substances, they do not

cause corrosion of the products packed in them, and they can be welded.

They have minimum permeability of water vapours and smells, and they transmit oxygen,

fats, and aromatic substances in a very limited amount. Generally, HDPE films are more

chemically resistant, which is given by their structure.

In the natural variant, HDPE films are suitable for direct contact with foodstuffs, the colour

variants only if the pigment content is within the concentration defined by the producer.

HDPE films are environmentally unobjectionable and recyclable, and they can be disposed

of in landfill or by combustion in which no substances harmful to the environment are released.

|

Main Fetures:

► Hot melt, torchable, easy to construction

► 7-10 microns thickness

► Environmental friendly, no residue

► Perforated performance, make the surface more flat

► More economical

Phameter:

| NO. |

Item |

Unit |

Factory parameter |

Detection method |

| 1 |

Appearance |

/ |

|

Q/TPXP1-2015 |

| 2 |

Thickness |

mm |

0.008-0.015 |

GB/T 6672-2001 |

| 3 |

Width |

mm |

1060-1070 |

GB/T 6673-2001 |

| 4 |

Max.Fd |

N/50mm |

15 |

GB/T 328.9-2007 |

| 5 |

Elongation at break |

% |

200 |

GB/T 328.9-2007 |

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer.

Q2: Do you provide samples ? is it free or extra ?

A2: Yes, we could offer A4 sample for free charge but if you need in roll,

we can offer 100-200m/roll for free, but shipping cost need you to paid.

Q3: How long is your delivery time?

A3: Depends on your quantity. Generally it is 15-20 days for 20GP container.

Q4: What's your payment?

A4: By L/C, by T/T (30% deposit before production, 70% balance before loading).

Q5: What's the usage of this film?

A5: It is special for the surface material when you producing SBS or APP bitumen

waterproofing membranes.

Q6: What's the thickness you can do?

A6: We can do as thin as 7 microns, but usually do 10 microns.

Q7: What's your production capacity?

A7: We have total 10 sets of machines, the production is about 1000 tons per month.

About Us:

UPASS, founded in 2008, is headquartered in New Materials Industrial Park, Qingpu District, Shanghai, and

has two production bases in Taicang, Jiangsu and Chenzhou, Hunan. UPASS adopts European professional

film manufacturing equipment and technology, mainly provides SDM strong cross film, various functional PE

release films (wrinkle / hydrophilic / non-slip / with tear-line / anti-aging, etc.), PE original film, PET , PP release

film, laminated film and other polymer film products. Related products are widely used in building waterproofing,

adhesive labels, medical care, electronic packaging, decoration, electronic optics and other fields. Especially in

the field of building waterproofing in China, UPASS occupies an important position.

UPASS will spare no effort in strengthening and improving the production, sales networks, service system to

return the trust and support of customers, and look forward to working with you in a win-win future.

Factory View:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!